How Suqaba makes meshing smart and reliable: A generative design use case

In manufacturing, engineering and design, before a new part or product is implemented in the real world, engineers test it in a virtual environment. These simulations help engineers replicate real world conditions and evaluate feasibility, durability and safety of the product. In short, simulation helps predict if the product meets the required specifications. Simulations are imperative in the design process and not only determine but also help save on cost and time of product development. Decisions made in this early design process can dictate up to 75% of the final lifecycle costs and therefore it is essential that simulation software provide reliable results.

Why Error Quantification Matters

Most simulation programs rely on approximation, the most common being the Finite Element Method (FEM), to solve the model. And while software has mastered the computation of this approximate solution, the same does not apply to error estimation, i.e. software do not provide a verifiable answer to the questions “How accurate is this approximate solution relative to the physics being modelled?”. So, simulation programs can show you stress maps and animations, but they can't tell you how accurate the solution is. If the gap is large, problems can slip through and resurface later such as safety recalls, unexpected repairs, or shorter product lifespans.

Without a clear measure of error, teams either make decisions in the dark, or implement heuristic methods and business rules that will merely mimic accuracy. The former can result in mistakes that detrimentally impact time, cost, and resources and the latter can cause significant cognitive fatigue, without guaranteeing accuracy anyway.

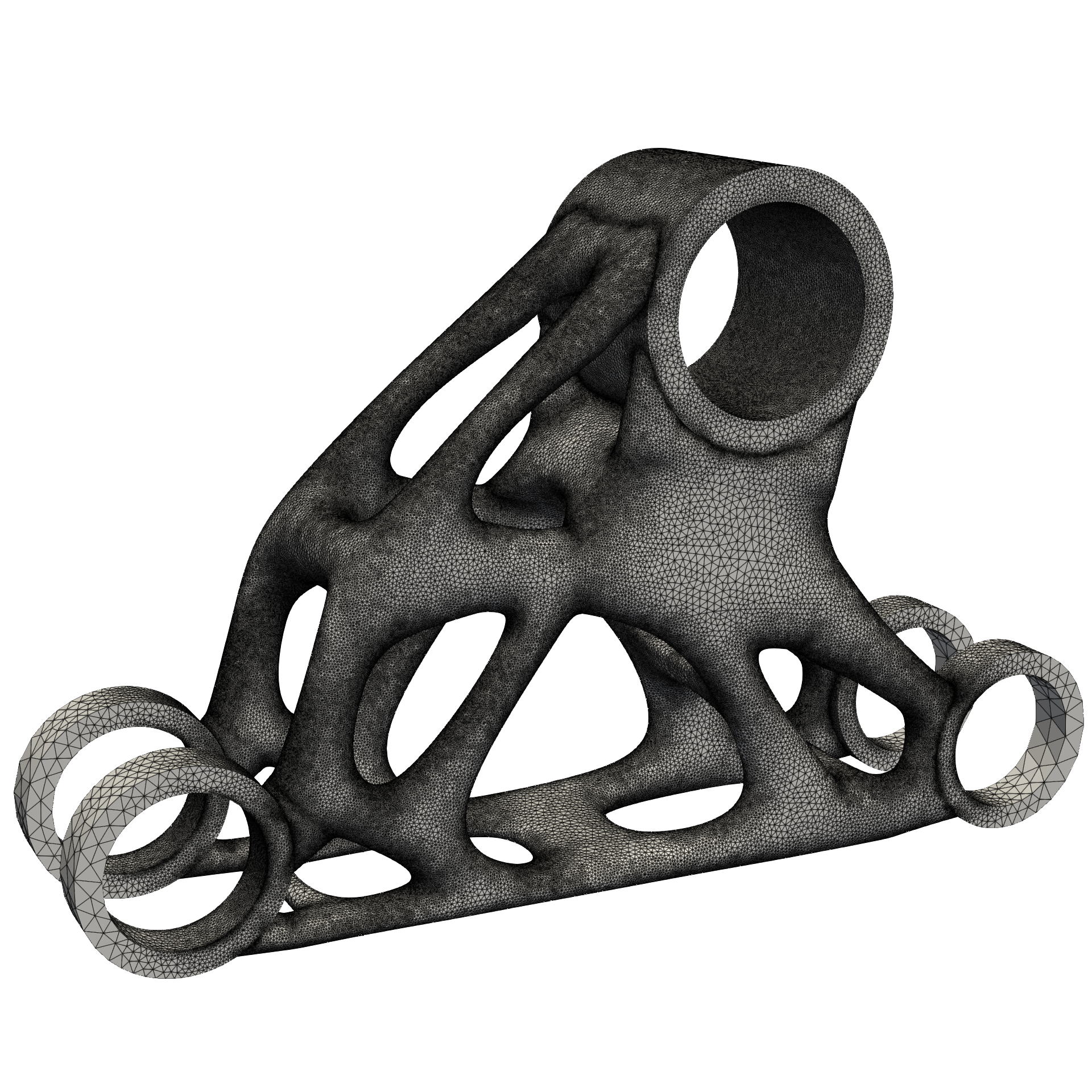

Bracket mesh for high-precision (<1% certified error)

Simulation with Error Control

Neither the loss of time, money and accuracy nor cognitive fatigue in the workforce are desirable in industries where accuracy and safety are paramount. Therefore, Suqaba offers simulation that is driven by error quantification and control, built with the driving belief that every simulation should come with its own quality check. The software calculates a certified error value for every simulation, no guesswork or unnecessary cognitive fatigue needed. Think of it as a built-in honesty meter. When the software detects a region where the error is high, it automatically refines the mesh in that region. When the error is small the mesh remains coarse. That way, their algorithm finds the soft spot between accuracy and compute cost. Engineers do not have to intervene or tweak settings by hand. The program handles verification in real time and shows a clear confidence level beside every outcome.

Key Features of Suqaba's Next-Generation Software

Suqaba's next-gen simulation software is built on a simple idea: deliver more in less time, with confidence in every result. By combining speed with reliability, it stands out as a powerful, efficient tool that brings real value to every stage of the design process.

Automatic mesh generation: You don't need to manually adjust the mesh or run trial-and-error studies to get accurate results. Suqaba takes care of it. The software builds the right mesh for your model automatically, so you can make faster decisions without getting stuck in technical details.

Error-driven refinement: Suqaba doesn't just run a simulation; it verifies its own work as it goes. If it finds areas where the result is not accurate enough, it adds more detail to it. Where things are already accurate, it simplifies the model to save time. That means more accurate results with less effort (on part of the user) than conventional simulation.

Built-in error checks: Every result in Suqaba comes with a certified error quantification. You'll know exactly how close the results are with respect to the physics being modelled, so there's no second guessing. This helps reduce risks and gives engineers confidence in their decisions.

Cloud-based and scalable: The software can be run from anywhere, whether you're working from your office, home, or on the go. It's built for flexibility and grows with your needs, so your simulations stay fast, efficient, and accessible, any time you need them.

By attaching a reliable measure of error to every result and adjusting itself until the numbers meet the required standards of the model, Suqaba helps engineers create safer, better products while keeping costs under control.

Bracket Case Study: Generative Design in Aerospace

To understand how this methodology applies to real-world applications, let's take a look at the summary of results of the static analysis of a bracket made by generative design for the aerospace domain.

The error tolerance was set to 1% to enforce a very high level of accuracy. The final certified error was evaluated at 0.9%, right below the target. This demonstrates the robustness of Suqaba's error quantification and adaptive meshing strategies. While such high-precision requirements naturally lead to longer compute times, they also provide engineers with results that can be trusted for high-stakes decision-making with reduced uncertainty. Now, let's explore the analysis output that plays a key role in interpreting simulation results.

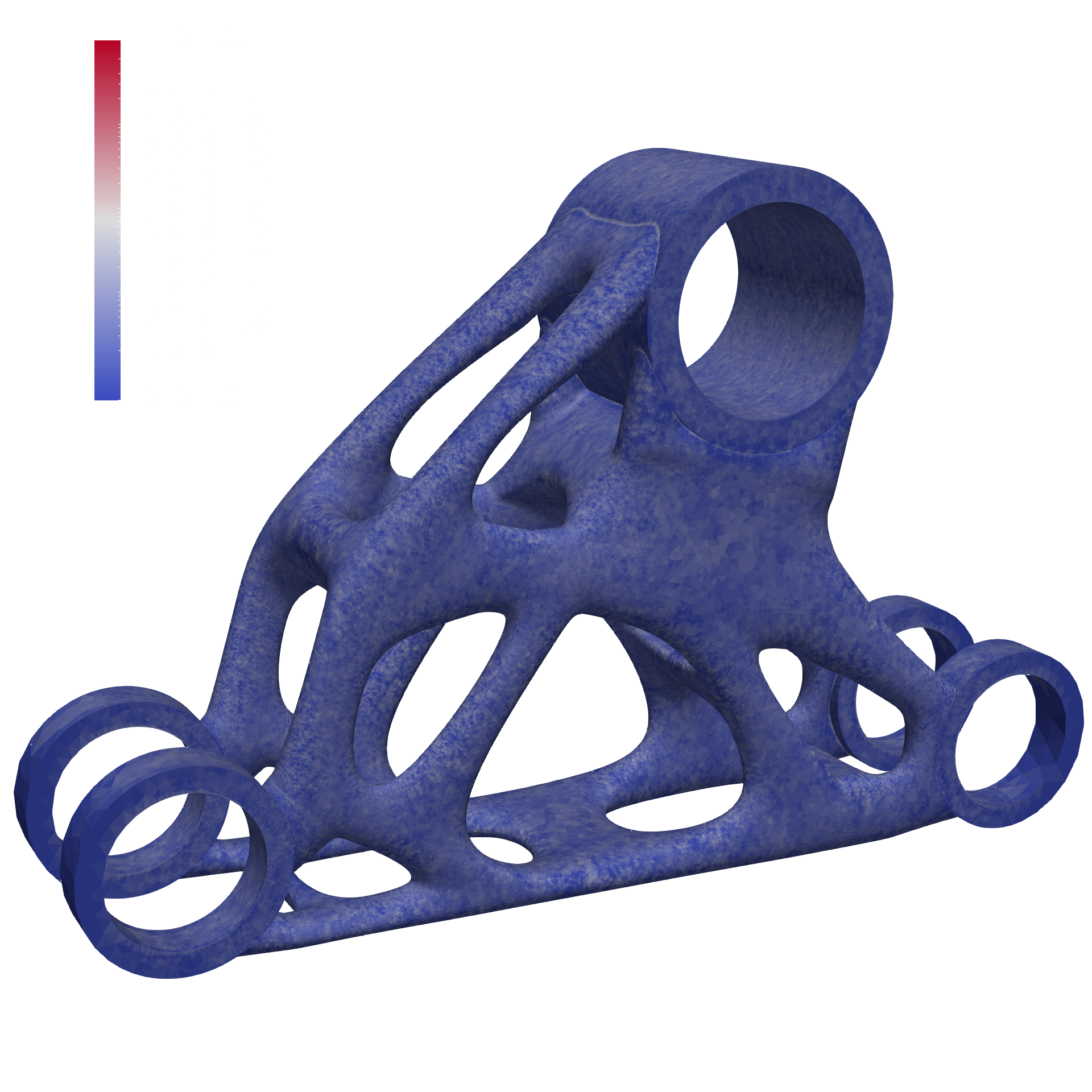

Quality Oracle view — Error distribution in the bracket (red: high, blue: low)

As part of the analysis output, Suqaba gives users something they rarely get from traditional simulation tools: a clear and measurable understanding of how accurate the results are (see the Quality Oracle view). At the heart of Suqaba's simulations is the concept of certified error, a measure of how far the results may deviate from the exact model solution. Users can select their own error tolerance depending on project needs:

10-15% for quick, rough checks or prototyping

2.5-10% for balanced trade-offs between accuracy and solving time

1% for the most demanding, safety-sensitive projects

This allows teams to adapt precision to the stage of development or design objectives. To calculate and track this error, Suqaba implements the well-established Constitutive Relation Error (CRE) estimator. It provides a strict and sharp upper bound of the error between the exact solution of your model (whose existence and uniqueness are required, though the exact solution itself is unknown) and the approximate solution computed by the solver.

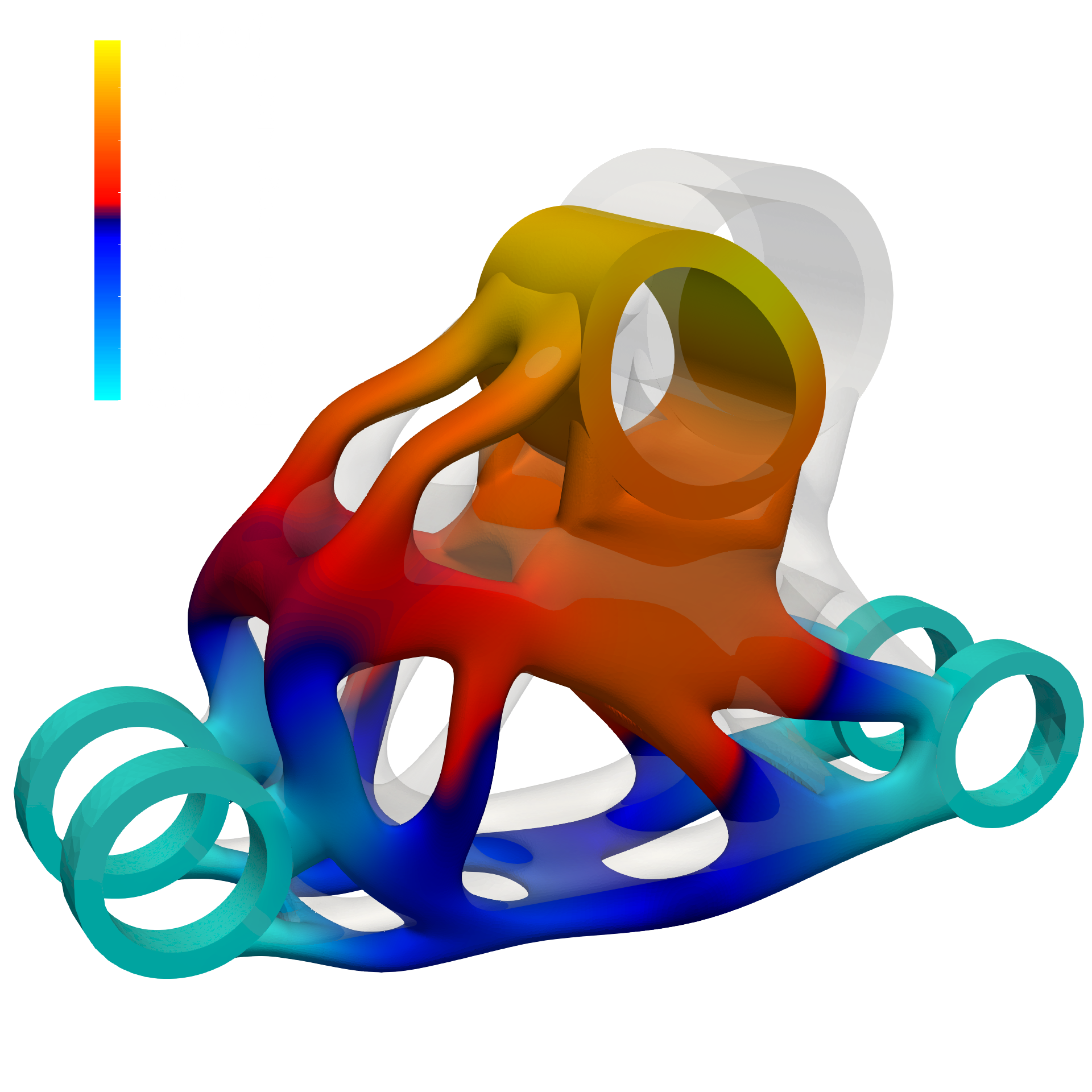

Displacement field on the deformed configuration (undeformed configuration in low opacity)

At Suqaba, the mesh is part of the simulation because the mesh is meant to adapt to the physics you're trying to model. What Suqaba built gives you both trust and speed: their simulation engine measures approximation errors and corrects it by refining the mesh where it matters and keeping it coarse where it doesn't; and it keeps doing that automatically until it reaches the level of accuracy you asked for.

Once the results are ready, it then provides a clear local error indicator, showing the confidence level for each part of the model. This means users can trust the output and make informed design decisions with clarity and precision, all while saving time and avoiding unnecessary complexity.

Overall, Suqaba simplifies the entire simulation workflow by removing guesswork and manual setup. Instead of relying on trial-and-error methods or user intuition only, the software automates critical steps, especially meshing, so engineers don't have to struggle with complex technical decisions.

For a visual overview, visit the LinkedIn short-form post showcasing the animation of mesh generation and adaptive refinement.